Understanding the Performance of Membrane Switches Over for Individual User Interface Gadget

The performance of membrane layer changes represents a significant development in customer interface design, integrating efficiency with aesthetic versatility. As industries significantly focus on customer experience, understanding the nuances of membrane button innovation ends up being crucial.

What Are Membrane Buttons?

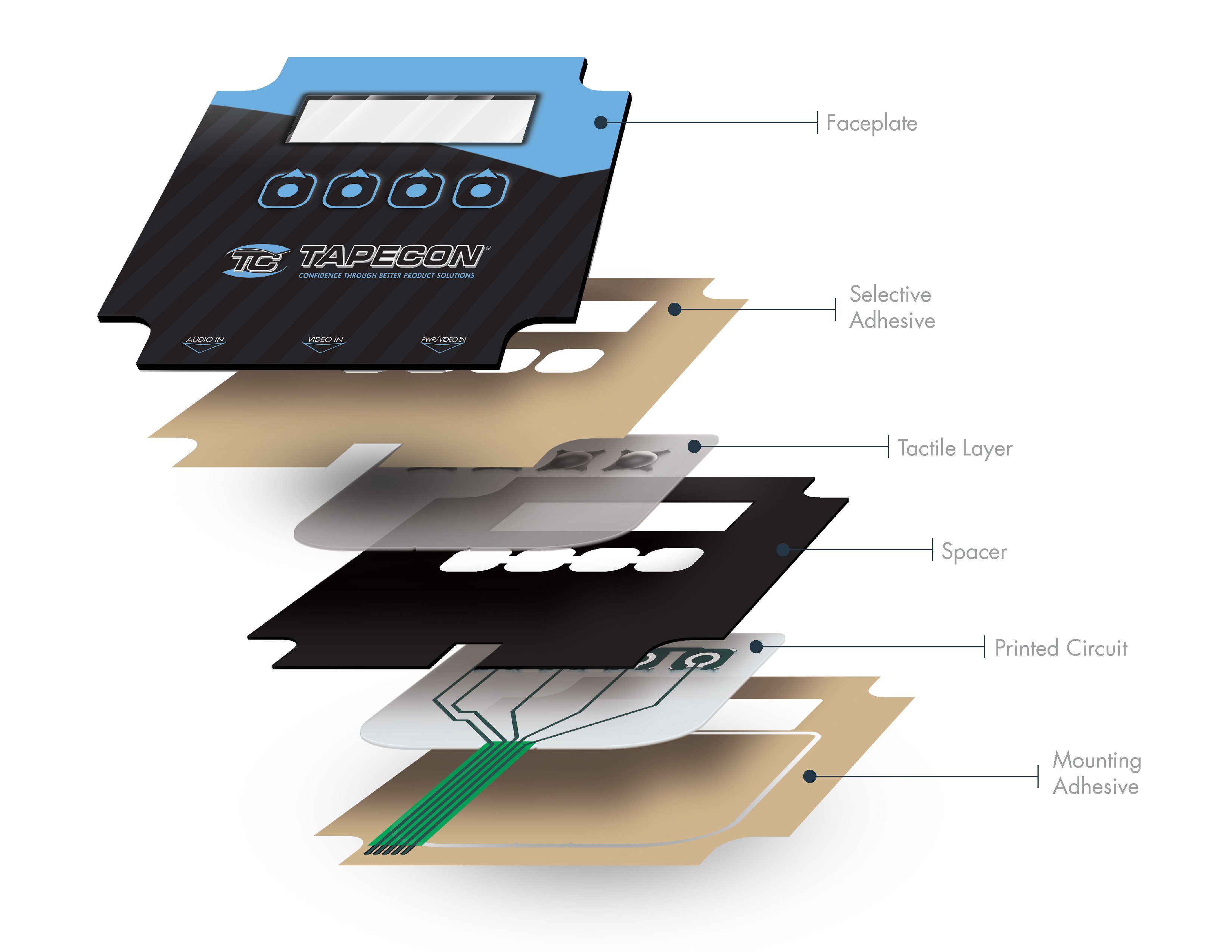

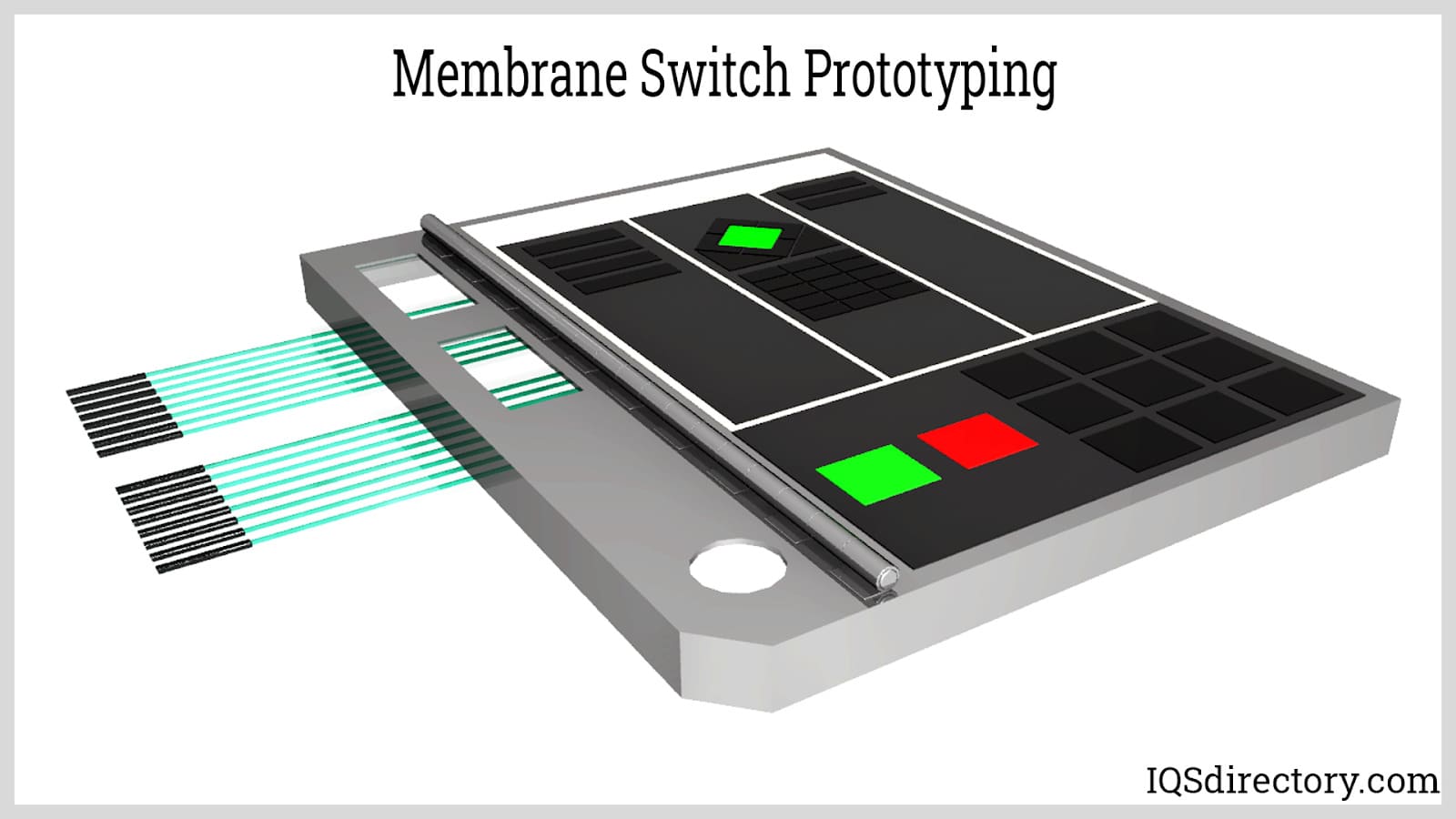

Membrane layer buttons are cutting-edge interface gadgets that assist in customer communication with electronic devices. These flexible elements contain multiple layers, including a graphic overlay, spacer, and a printed circuit layer. The layout enables a smooth combination right into various electronic gadgets, enhancing both the aesthetic and practical facets of user interfaces.

Membrane layer switches are commonly used in a large range of applications, from household home appliances to industrial machinery and clinical devices. Their building and construction generally includes a slim profile, making them an ideal option for compact layouts. The tactile responses supplied by these switches can be crafted to fulfill specific customer choices, guaranteeing reliable communication in between the customer and the gadget.

Sturdiness is one more substantial advantage of membrane layer switches, as they are immune to dirt, dampness, and chemicals, which improves their lifespan in demanding settings. Furthermore, these buttons can be personalized in terms of form, size, and graphic style, allowing for branding and user-specific attributes. In general, membrane layer switches stand for a sensible remedy for boosting user experience in electronic devices, combining performance with visual allure in an efficient way.

Just How Membrane Layer Switches Work

Operating on a simple principle, membrane changes use a split construction to sign up user input successfully. Each button is composed of several layers, including a printed circuit layer, a spacer layer, and a top graphic layer, which are developed to interact seamlessly. When a user presses the top layer, it compresses the spacer layer, bringing the conductive aspects of the circuit layer into call with each various other.

This call creates a closed circuit, signifying the tool to perform a details feature. The style permits various configurations, including tactile feedback, which can boost the customer experience by giving a physical sensation upon activation. The materials utilized in membrane buttons usually consist of versatile substratums, such as polyester or polycarbonate, which ensure toughness and resilience versus wear and tear.

Trick Benefits of Membrane Buttons

Another significant advantage is their density. Membrane buttons are slim and light-weight, news which enables suppliers to save area in their gadgets without sacrificing performance. This feature is particularly beneficial in applications where weight and volume are important factors to consider.

In addition, membrane layer switches are immune to dust, dampness, and chemicals, enhancing their toughness. This durability extends their lifespan and minimizes the demand for frequent substitutes, resulting in expense financial savings in time.

Furthermore, the tactile comments supplied by membrane buttons can be maximized to enhance individual communication. They can include attributes such as raised switches or audible clicks, enhancing functionality and customer experience.

Applications Across Industries

Interface devices utilizing membrane switches are prevalent in a large variety of markets, showcasing their versatility and capability. Membrane Switch. In the clinical field, membrane buttons are essential to gadgets such as diagnostic equipment and person surveillance systems, where their longevity and simplicity of cleaning are critical for preserving health requirements. In the automotive sector, these buttons are used in control panel controls and infomercial systems, providing a sleek and modern interface for users.

In addition, the customer electronics market take advantage of membrane layer buttons in devices and handheld gadgets, where compact layout and user-friendly interfaces improve user experience. Industrial applications also utilize membrane changes for control panels in machinery and automation systems, emphasizing their toughness and resistance to severe atmospheres.

In the aerospace and protection sectors, membrane layer buttons are used in cabin controls and tools, where dependability and performance under severe conditions like this are vital. In addition, the video gaming sector progressively incorporates membrane layer buttons in controllers and arcade makers, adding to an appealing customer experience. In general, the adaptability of membrane layer changes enables their widespread use across various industries, highlighting their value in contemporary interface style.

Future Trends in Membrane Layer Change Technology

Furthermore, using innovative materials, such as polycarbonate and polyester films, is anticipated to climb, providing improved toughness and resistance to environmental stress factors. These products add to the total longevity of membrane buttons, making them appropriate for harsher commercial applications.

Moreover, the consolidation of smart innovation, including IoT connection, will certainly make it possible for membrane layer buttons to communicate with other devices and systems, assisting in an extra interactive user experience. This pattern straightens with the growing demand for smart tools throughout different industries, from medical care to customer electronics.

Last but not least, customization choices are expected to increase, enabling manufacturers to create bespoke options tailored to details customer needs and choices. These growths will certainly position membrane buttons as important parts in the advancement of individual interface innovation.

Verdict

In final thought, membrane switches over represent a crucial improvement in interface technology, supplying a trusted and versatile solution for varied electronic applications. Their layered building assists in small design, while features such as tactile responses enhance customer interaction. The longevity versus ecological aspects even more solidifies their utility across multiple markets. As innovations in product science and touch noticing technologies proceed, the performance and applicability of membrane layer switches are anticipated to expand, enhancing their value in modern-day electronic devices.